Implementación del ensayo para calcular la eficiencia de un motor de hasta 2,4 kW en función de la determinación de la potencia mecánica en el eje, por medios opto-eléctricos

Main Article Content

Abstract

The objective of this work is the adaptation and implementation in the Applied Energy Efficiency Laboratory (LEEA) of the UTN La Plata, of a novel measurement method developed by researchers from the University of Durham (United Kingdom) and the Universidad Politécnica delle Marche (Italy) . This method allows to determine the mechanical power in the shaft of an asynchronous electric motor by opto electric means, and in the LEEA it will be used to determine the energy efficiency for different load states. These tests are carried out with 2.4 kW De Lorenzo equipment belonging to the Electrical Machines Laboratory.

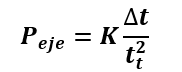

To determine the energy efficiency of the motor, the methodology is based on the measurement of the electrical power consumed and the mechanical power that an electric motor delivers on its axis. To measure the electrical power, a Fluke 235 power and energy meter is used and to obtain the power in the motor shaft, the torsional deformation that occurs in a metal rod that links the motor under test with a variable mechanical load on the shaft is measured. It is proportional to the torque. The torsional deformation is obtained by photoelectric sensors located at each of the ends of the metal bar. The main equation used is:

where:

tt: Time between pulses of a complete revolution measured on the same sensor, motor side and ∆t: Time between pulses motor side-generator side

K: is a constant that is determined by testing the torsion bar, applying a known torque and measuring the angle of deformation.

The results obtained so far (postponed in part by the Pandemic) have focused on finding the constant K.

In conclusion, we can affirm that the method is low cost, easy to apply in the LEEA laboratory. The steps to follow, is establish an error table for different load states, taking a class 0.2 torque meter as a comparison pattern.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

IEC 60034-30 (2014). Standard on efficiency classes for low voltage AC motors.

Zappalá D., Bezziccheri M., Crabtree C. y Paone N. (2018). Non-intrusive torque measurement for rotating shafts using optical sensing - of zebra-tapes. Measurement Science and Technology, 29(6), 065207.